As it might be known to many that metal parts are very hard to polish. However, polishing is a rather expensive cost when it comes to steel, even if it’s just to make one prototype.

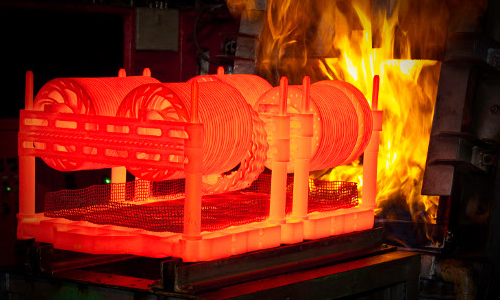

The most obvious answer would be polishing off the oxidation layer. Stainless steel has become stained of the steel. The black oxidation layer on the part surface is unevenly distributed: it looks like black stains were smudged on the surface. The only difference is that the lower part has been hardened (to 55HRC). The part below is also a part made out of stainless steel. The part hasn’t gone through any treatment such as hardening, and the part looks shiny and steel-like with some CNC tool-marks visible on the surface. However, we have come across a client who cares a lot about the aesthetics of a hardened steel part.Īs you could tell from the parts in the above photos, one is a part we machined out of stainless steel. It also enhances the wear resistance of a variety of metals or alloys.Īfter the hardening procedure, the steel part will have a black and uneven oxidation layer, which many people find it displeasing but acceptable.By applying this technique metal become extra flexible and steel becomes exceptional solid.This process is magical because it increases the life span of different tools.Case hardening produces more durable products like steel tools.This procedure is beneficial to objects that require a strong exterior to withstand wear and tear while preserving a soft interior to absorb shock. Thirdly, a case hardened part is easier to be welded than the part that hasn’t been hardened. For parts that require extreme hardness, it is the ideal way to machine a mild steel material, then use case-hardening to make the part as hard as required. It is universally known that steel parts are hard to machine. Secondly, case-hardening makes it easier for steel parts to be machined. Typically, it saves money in the long term because you could use it longer and don’t have to purchase it often. Retention of a softer core makes the part be able to absorb and release stress. The carburized steel can be hardened again by flame or induction hardening since the carburized steel parts will have enough carbon content to be hardened again.įirstly, since case-hardening improves the hardness of the hardened metals significantly while keeping the core of the steel part comparably soft and flexible, the steel part becomes much more wear-resistant. In this procedure, steel parts will be placed in a carbon-enriched atmosphere and heated to 9000c for a certain amount of time, and then the steel will be subsequently quenched so that the carbon is locked inside the steel parts. Carburizingįor steel parts that contain carbon at a range of 0.1-0.3wt%C, the surface-hardening technique of carburizing is a good option.

Elements such as chromium, molybdenum, and aluminum will have to be used in this method to form nitrides, which makes the steels parts case-harden. The depth of the hardened surface depends on how much time the steel parts have stayed in the ammonia environment. Nitriding is another form of case hardening technique, during which the steel parts s heated to a range of 484-621℃ in ammonia and dissociated ammonia environment. Only steel or iron that have enough carbon content will have good results with this flame hardening, the carbon content has to be 0.3-0.6wt%C, for steel or iron material that has less carbon content than that, there are other processes such as nitriding and carburizing. As you might guess from the name, this metal case hardening process involves flames or heat, during which a high-carbon content steel part is heated to an extreme temperature by oxy-gas flame or by induction heating, then the heated carbon steel part will be cooled quickly by a coolant (usually water). The first one “heating and quenching” is also called flame or induction hardening. There are 3 common case-hardening processes.

0 kommentar(er)

0 kommentar(er)